MOHS HARDNESS SCALE

Mar 23, 2022

Mohs

Hardness Scale is a scratch-

hardness evaluation of materials and is the oldest

hardness evaluation. The Mohs

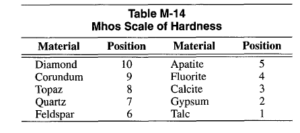

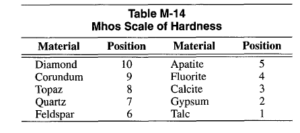

Hardness Scale (circa 1822) was developed by mineralogists and is based on the capability of a harder material to scratch the surface of a softer material. The ten minerals listed in Table M-14 were selected to form the Mohs

scale, and each makes a permanent scratch (one that cannot be rubbed off) on all minerals listed below it. There is a very great difference between diamond and corundum compared to the relatively small differences between softer minerals. A human fingernail can scratch gypsum. A

hardness approximation of a polished

metal surface can be obtained by determining which pair of adjacent minerals scratch and do not scratch the sample. Hardened tool

steel is between 8 and 9 on the Mohs

scale. Low

carbon steel is usually between 3 and 4, while annealed

copper is between 2 and 3. The Mohs scratch

test is not normally applied to metals because of its semi-quantitative nature; however, a uniformly applied scratch with the tip of a sharp needle across the face of a polished and etched metallographic specimen can give useful information on the metal’s microconstituents. Careful observation and perhaps measurement of the scratch width along its length, can provide an indication of the relative hardness of the microconstituents. See HARDNESS TESTING.

Back to Glossary Index Page