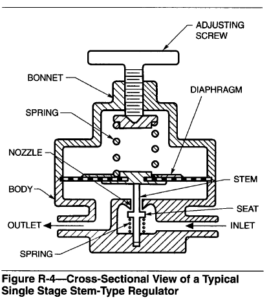

Regulators are reducing valves which are attached to the cylinder valves of oxygen, acetylene, and other gas cylinders to reduce the pressure in the cylinder to a suitable working pressure at the torch. The components of a regulator are: a diaphragm, a seat, a nozzle, springs, and a suitable case, usually made of a brass forging. A cross sectional view of a typical single-stage regulator is shown in Figure R-4.

Regulator Types

There are two general types of regulators: the single-stage regulator and a more complex two-stage regulator. A two-stage regulator has two seats, two nozzles and two diaphragms, with one adjusting screw.

Regulator Action

When the adjusting screw is turned to the right, pressure is applied to the spring, causing the diaphragm and the seat carriage to force the seat away from the nozzle, permitting gas to enter the chamber. The high-pressure gas entering the chamber increases the pressure on the diaphragm until it overcomes the pressure of the large spring, permitting the seat to be closed by the small spring, or springs. The position of the seat over the nozzle is controlled by the difference in balance between the pressure of the spring and the pressure of the gas in the chamber; this maintains a constant flow of gas through the regulator at a given pressure. This pressure may be increased or decreased by changing the position of the adjusting screw.

A single-stage oxygen regulator is usually used to step the pressure down from a cylinder pressure of 13.8MPa (2000 psi), when the cylinder is full, to torch pressures of from 7 to 240 kPa (1 to 35 psi), depending on the size of the tip in use and the type of torch. A 21 MPa (3000 psi) gauge is attached to the high- pressure side of the regulator and a gauge which will reduce pressure to 1 MPa (150 psi) or less is attached to the low-pressure side. The initial reduction in a two-stage oxygen regulator is from a maximum of 13 MPa (2000 psi) to an intermediate pressure of 1.7 MPa (250 psi), the second reduction is to the required torch pressure, which is controlled by the adjusting screw.

Acetylene regulators reduce cylinder pressures from a maximum of about 1.7 MPa (250 psi) to torch pressures not ordinarily exceeding 75 or 82 kPa (11 or 12 psi). These are usually equipped with 2.7 MPa (400 psi) gauges on the high-pressure side and 340 kPa (50 psi) gauges on the low pressure side.

Connections

The standard inlet threading of the nuts and nipples of oxygen and acetylene regulators is different to prevent attaching the regulators to the wrong cylinders.

The threading of the outlet nipples for the hose connections also differ so that hoses cannot be interchanged. See HOSE CONNECTION STANDARDS.