Oxygen lance cutting (LOC) is an oxygen cutting process that uses oxygen supplied through a consumable steel pipe or lance. The preheat required to start

the cutting is obtained by other means.

The earliest version of LOC used a plain black iron pipe as a lance, with oxygen flowing through it. An improved version of the lance involves a number of low-carbon steel wires packed into the steel tube. This increases the cutting life and capability of the lance. Commercially available tubes are typically 3.2 m (10-1/2 ft) long and 16 mm (0.625 in.) in diameter.

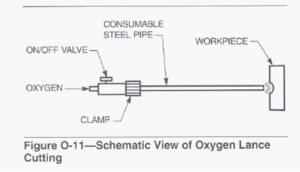

An oxyfuel gas cutting or welding torch is used to heat the cutting end of the lance to a cherry red, and then the oxygen flow is started. The iron pipe bums in a self-sustaining, exothermic reaction, and the heating torch is removed. When the burning end of the lance is brought close to the workpiece, the work is melted by the heat of the flame. The oxygen lancing operation is shown schematically in Figure 0-11,

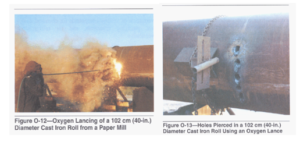

Oxygen lance cutting can be used to pierce virtually all materials. It has been used successfully on aluminum, cast iron, steel, and reinforced concrete. Oxygen lancing of a 1m (40 in.) diameter cast iron roll used in a paper mill is shown in Figure 0-12. Cutting oxygen was supplied at 550 to 870 Wa (80 to 120 psi). Holes pierced in the roll are shown in Figure 0-13. The variable angle bracket shown in Figure 0-13 was found to be helpful in guiding the lance.

A 64 mm (2-1/2 in.) diameter hole can be made in reinforced concrete at a rate of about 100 mm/min (4 in/min). The process has been used to open furnace tap holes and to remove solidified material from vessels, ladles, and molds. It can be used to cut refractory brick, mortar, and slag. The LOC process can be used underwater. The lance must be lighted before it is placed underwater, but then piercing proceeds essentially the same as in air. The process produces a violent bubbling action which can restrict visibility.

Arc-Started Oxygen Lancing. A variation of the oxygen lancing process uses an arc to start the iron-oxygen reaction. This equipment uses tubes typically 45 cm (18 in.) long and either 6.4 or 9.5 mm (0.25 or 0.375 in.) in diameter. A 12-volt battery can be used as

a power source, with the cutting tube connected to one battery terminal and a copper striker plate connected to the other.

To start the burning operation, the operator starts the oxygen flow and draws the steel tube across the copper plate at a 45o angle. Sparking at the copper plate will ignite the tube. The burning rod can then be used for cutting, piercing, or beveling steel. It can also be used to remove pins, rivets, and bolts.