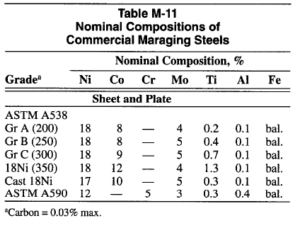

Maraging steels are a group of iron-nickel alloys characterized by a combination of high strength and toughness. They are strengthened by precipitation of one or more intermetallic compounds in a matrix of essentially carbon-free martensite. In addition to nickel, these steels generally contain either molybdenum, titanium, aluminum, and either cobalt or chromium. The nominal compositions of six commercial alloys are shown in Table M- 11.

To achieve optimum properties, the carbon and impurity elements in maraging steels are deliberately kept very low.

Properties. Differences in physical properties between maraging and mild steels are not significant, except for thermal conductivity. Heat loss by conduction during welding would be lower in maraging steels. Maraging steels are noted for toughness and high strength. The Charpy V-notch and fracture toughness properties are more than twice those of conventional quenched and tempered high-strength steels. To a great extent, toughness is dependent on the purity of the steel. The maximum service temperature for

maraging steels is about 400°C (750°F). Above this temperature, long- term strength drops off rapidly due to overaging.

Welding. Gas tungsten arc welding (GTAW) is the most widely used process for welding maraging steels, but they are readily welded by most arc welding processes. The GTAW process allows good control of heat input and protection from weld oxidation. Gas

tungsten arc welded joints have better toughness than those made by gas metal arc welding.

Procedures.Welding procedures and postweld heat treatment procedures vary with the alloy being welded, and the steel manufacturer’s recommendation should be followed. Filler metal of the same composition as the base metal should be used. In general, the

following rules apply:

(1) No preheat is required. However, if the temperature of the metal falls below 0°C (32oF), it is best to preheat the weld joint area to 21°C (70°F).

(2) Anneal at approximately 815°C (1500°F).

(3) Austenite aging (ausage) should be at approximately 700°C (1300°F).

(4) Perform cold working, if necessary or required.

(5) Refrigerate (if possible) at -73°C (-100°F).

(6) Marage (martensite age) at approximately 480°C (900°F).

(7) Cool in still air.