See THERMAL GOUGING.

Electric arc and oxyfuel gas cutting processes can be used for gouging. Gouging is usually done to cut a groove or bevel in a workpiece to prepare it for welding.

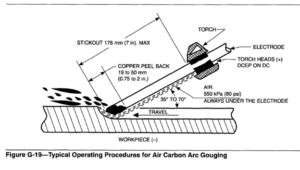

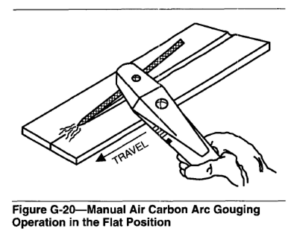

In manual air carbon arc gouging, the electrode should be gripped as shown in Figure G-19, so that a maximum of 178 mm (7 in.) extends from the cutting torch. For nonferrous materials, this extension should be reduced to 75 mm (3 in.). The air jet should be turned on before striking the arc, and the cutting torch should be held as shown in Figure G-20. The electrode slopes back from the direction of travel with the air jet behind the electrode. The arc may be struck by lightly touching the electrode to the workpiece. The electrode should not be drawn back once the arc is struck. Under proper operating conditions, the air jet will sweep beneath the electrode end and remove all molten metal. The gouging technique is different from that of arc welding because metal is removed instead of deposited. A short arc should be maintained by progressing in the direction of the cut fast enough to keep up with metal removal. The steadiness of progression controls the smoothness of the resulting cut surface.

When gouging a workpiece in the vertical position, gouging should be done downhill, to let gravity assist in removing the molten metal. Gouging in the horizontal position may be done either to the right or to the left, but always in the forehand direction. In gouging to the left, the cutting torch should be held as shown in Figure G-20. In gouging to the right, the cutting torch will be reversed to locate the air jet behind the electrode. When gouging overhead, the electrode and torch should be held at an angle that will prevent molten metal from falling on the operator.

The depth of the groove produced is controlled by the travel speed. Slow travel speeds produce a deep groove; fast speeds produce a shallow groove. Grooves up to 25 mm (1 in.) may be cut. The width of the groove is determined by the size of the electrode

used and is usually about 3.2 mm (1/8 in.) wider than the electrode diameter. A wider groove may be made by oscillating the electrode with a circular or weaving motion.

When gouging, a push angle of 35″ from the surface of the workpiece is used for most applications. A steady rest is recommended in gouging to ensure a smoothly gouged surface, particularly in the overhead position. Proper travel speed depends on the size of the electrode, type of base metal, cutting amperage, and air pressure. An indication of proper speed and good gouge quality is a smooth hissing sound in the arc. See also ARC GOUGING, BACKGOUGING, OXYGEN GOUGING, PLASMA ARC GOUGING, and AIR CARBON ARC CUTTING.