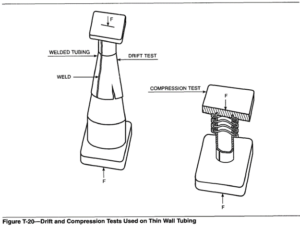

Tubing is tested by one of several destructive or nondestructive methods. These tests are shown in Figure T-20.

Drift and Compression Tests

The drift test consists of placing a hardened steel pin in a tube or vessel made of thin sheet metal, and applying pressure with a manual or power-driven hammer until the tube or vessel is split, either in the weld or elsewhere. The compression test is a crushing test used with tubing, which forces the tubing into folds, thus indicating both strength and ductility of the weld metal. Both of these tests are confined to tubing and to small sheet metal parts.

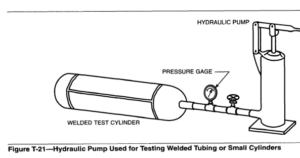

Hydraulic Tests

These tests are common for testing welded tanks, barrels, or cylinders when they can be filled with water. The pressure is applied with a small hydraulic pump, as indicated in Figure T-21. This test can be applied to the destruction of the tank if so required. It may also be applied at a pressure which will not destroy the tank or strain the metal or welds beyond the elastic limit. It is a relatively simple test to make; the only apparatus required is a pump, a gauge, and a valve. Sometimes the test pressure used is three times the working pressure, but as a rule, weld defects in tanks will be indicated when tested and hammered at 1-1/2 times the working pressure.

Air Pressure Tests

Air pressure should not be used for testing tanks, because air compresses into a smaller space than water. For example, if a tank were filled to a pressure of 550 or 690 kPa (80 or 100psi), and the weld should break, the air will expand with such violence that injury to persons in the vicinity could occur. Water under pressure, on the other hand, does not expand, and when a tank breaks, the break occurs with a harmless spurt of water.

A portable tensile testing apparatus is a valuable piece of equipment, particularly useful in the field to test the strength of specimens cut out of pipe or tank welds. It consists of a hydraulic cylinder with jaws to clamp the specimen and a pump to increase the pressure within the cylinder. The jaws of the clamp are pulled apart by hydraulic pressure until the specimen breaks. See TENSILE TEST.