Plasma arc gouging is an adaptation of the plasma cutting process. For gouging, arc constriction is reduced, resulting in a lower arc stream velocity. The temperature of the arc and the velocity of the gas stream are used to melt and expel metal in a similar

manner to other gouging processes. A major difference compared to other gouging processes is that the gouge is bright and clean, particularly on nonferrous material such as aluminum and stainless steel. Virtually no post-cleaning is required when the plasma

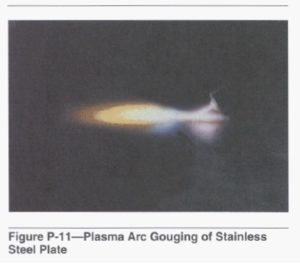

gouged surface is to be welded. A plasma arc gouging operation on stainless steel plate is shown in Figure P-11.

Equipment

The basic equipment for plasma gouging is the same as for plasma cutting. Most plasma cutting equipment can be used for plasma gouging provided that the volt-ampere output curve of the power source is steep enough and the voltage high enough to sustain

the long arc used for plasma gouging.

The torch utilizes a gouging tip which is designed to give a softer, wider arc and proper stream velocity.

The torch used is the same as a plasma cutting torch and may be either single- or dual-gas flow and air or water cooled.

Gases

The recommended plasma gas for all gouging is argon plus 35 to 40% hydrogen. The gas can be supplied from cylinders or prepared using a gas-mixing device. Helium may be substituted for the argon-hydrogen mixture, hut the resulting gouge will be shallower. The secondary or cooling gas, when used, is argon, nitrogen, or air. Selection is based on brightness of gouge desired, fume generation, and cost.

Air is sometimes used for the plasma gas on air operating systems but is generally limited to carbon steel gouging. Most manual air cutting systems are limited to 100 A output and this restricts the size and speed of plasma gouging.

Operating Procedure

The technique for plasma gouging is essentially the same as for other gouging methods. The torch is angled approximately 30” from the horizontal. Gouge depth is determined by speed of travel. It is important not to attempt removal of too much metal in a single pass.

Applications

Plasma gouging can be used on all metals. It is particularly effective on aluminum and stainless steel, where the gouges produced are clean and devoid of any carbon contamination. See PLASMA ARC, PLASMA ARC WELDING, and PLASMA ARC CUTTING.