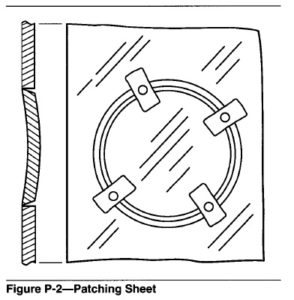

A sheet of material used to place a patch in a flat, round or warped plate where cracking has occurred or is expected to occur during or after welding, or while in service. See Figure P-2. The cross section of the diagram shows that the patch is slightly dished to allow for contraction in the weld. The preferred circular patch shape equalizes stresses around the weld. However, if a circular patch is not practical, a patch shape as nearly circular as possible, such as oval or elliptical, should be used. If the opening is rectangular, corners of the patch and opening should be rounded. Where equipment for forming a dished patch is not available, the patch can be dished by hammering, which should be done when the plate is hot. The diagram shows a simple method for holding the patch in place. Holes are drilled through at the joint, and bolts are used to clamp lugs on both surfaces of the patch. See also CORRUGATED PATCH.