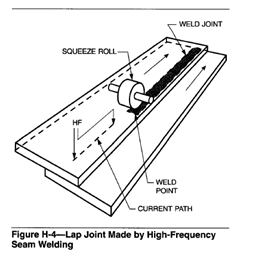

A group of resistance welding process variations that use high frequency welding current to concentrate the welding heat at the desired location. See Figure H-4. See also HIGH-FREQUENCY SEAM WELDING and UPSET WELDING.

High-frequency resistance welding is a forge welding process in which the faying surface is heated to plastic welding temperatures by using power in the range of 400 to 450 kHz. Power is introduced to the weldment through small contacts sliding or rolling

directly on the metal to be welded. The process is continuous, and produces a strong forge weld when the heated parts are passed in line through squeeze rolls.

The process is particularly suited for continuous production of large volumes of tubular and similar products. Welds can be made without filler metal, at speeds to 300 dmin (1000 ft/min) in ferrous, non-ferrous, exotic and dissimilar metals, in thicknesses of 0.1 to 16 mm (0.0045 to 0.625 in.). Users are able to achieve high production rates with a variety of metals, and are able to weld many of the high-strength alloys that often prove troublesome when other welding processes are used.